Kukanganisa kwemafomati eemail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

News

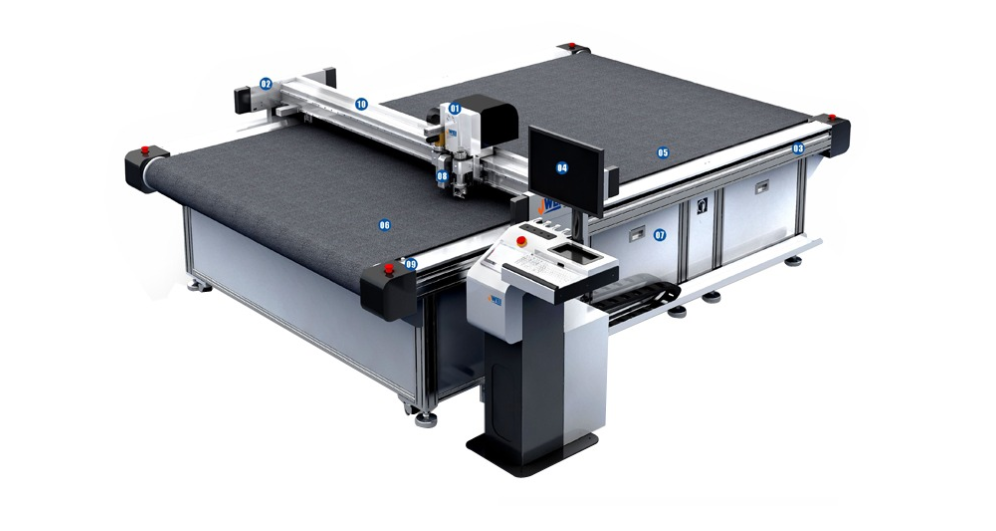

Method of Slotting Compensation for CNC Bench Cutting Machine

There are two main methods of slotting compensation for CNC Table cutting machines. The contour is processed through the combination of software and hardware. Next, let's follow the miner to see the methods of slotting compensation and related expanded knowledge!

Method of slotting compensation for CNC bench cutting machine

CNC cutting machine supports two cutting compensation methods: "hard compensation" and "soft compensation". Complete "hard compensation" through the command g41/g42 on the CNC system of the machine tool. When the CNC cutting machine is programmed automatically, the corresponding compensation command will be automatically generated according to the contour attribute.

"Soft compensation" is the isometric zoom function of the part outline to be realized. After creating the layout drawing with the part spacing set by the user, the CNC cutting machine will automatically scale all contours equidistantly according to the set slit compensation value, and directly generate the NC code of the scaled contour in the process of automatic programming. CNC cutting machine has the interlock function of "hard compensation" and "soft compensation" to avoid repeated compensation. It is worth pointing out that if ordinary trimming is required, soft compensation should be used.

Compensation calculation description of laser cutting machine

The term "cutting compensation" for a CNC cutting machine comes from a CNC flame cutting machine. However, with the development of science and technology, there are a series of cutting products, such as plasma cutting machines, laser cutting machines, water jet cutting machines, and so on, but they all have a common disadvantage, that is, cutting the size of the workpiece into a certain size in the processing process. The cutting process needs to be 1-3mm smaller than the actual drawing size. To solve this problem, "cutting correction" plays an important role.

When cutting flame, plasma, laser, water jet, wire cutting machine and other CNC cutting, the cutting path according to CNC criteria is the theoretical size, and the actual cutting size slightly deviates. This is because there is a cut in the cutting process, which is the part lost in the cutting process. Therefore, if geometric dimension correction is not performed, the length of the outer contour part of the actual cut-in part size will be shorter. The internal outline size is increased (different on both sides. Cutting width is half different on one side).

Geometric size compensation is required to compensate for size differences caused by cutting losses. Compensation is divided into software compensation and CNC system compensation. The purpose is to offset the trajectory of the cutting machine so that cutting losses occur. It needs to be formed after cutting, and its size is the same as that of the programming diagram. This can be easily solved by nested software. When programming nesting software, the software calibration only needs to input programming parameters (compensation radius), and when generating CNC code, the geometric dimension will automatically offset according to the inner contour and outer contour. It can also be generated from CNC code, so the CNC system can continue to calibrate according to the following contents. Offset direction is compensated. When the software compensation amount is set to 0, no compensation is generated, but the compensation command still exists and can be compensated by the CNC system during the cutting process.

When setting the cutting compensation, please pay attention to the following points:

- After setting the software calibration, it is usually not necessary to calibrate in the CNC system. Otherwise, there will be a deviation in the repetition size of calibration. However, if the software calibrates the size after cutting, it can be recalibrated through the CNC system.

- If compensation is carried out through the CNC system, the compensation amount needs to be set to 0 in the software.

- If you are not sure about the size to be calibrated, you can cut a square on the leftover material, and then measure the actual size and the programmed size to calculate the required compensation.

- The CNC system is difficult to deal with the compensation of small arcs, and arcs smaller than or smaller than the compensation radius cannot be cut and accurately compensated. In this case, you should consider modifying the part. Consider using pictures or software compensation to help you find problems in time.