Kukanganisa kwemafomati eemail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

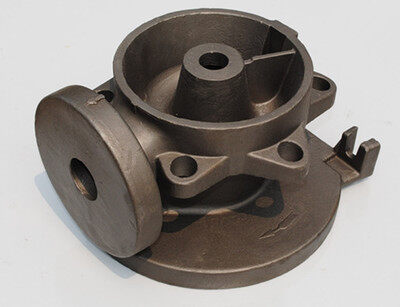

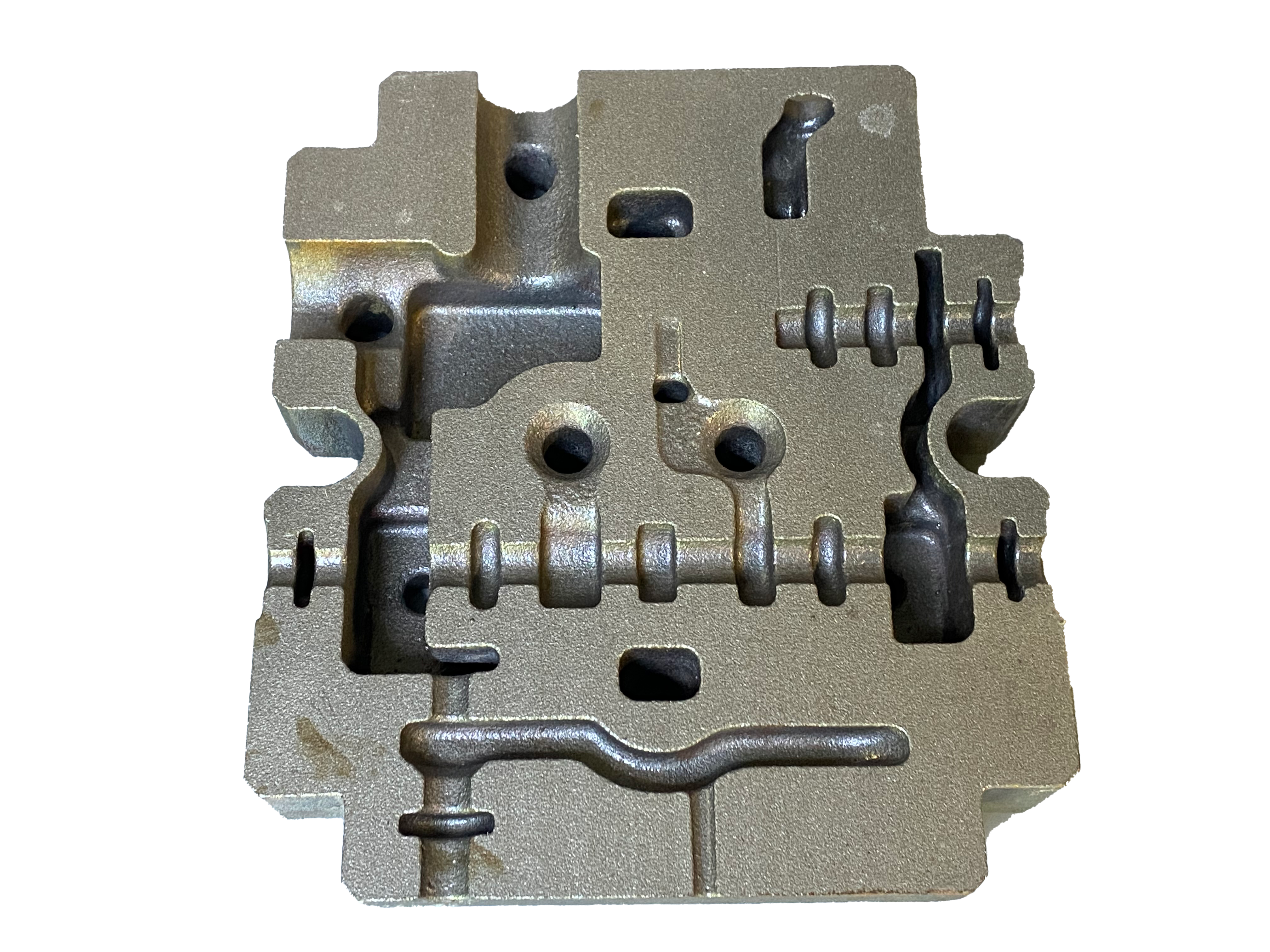

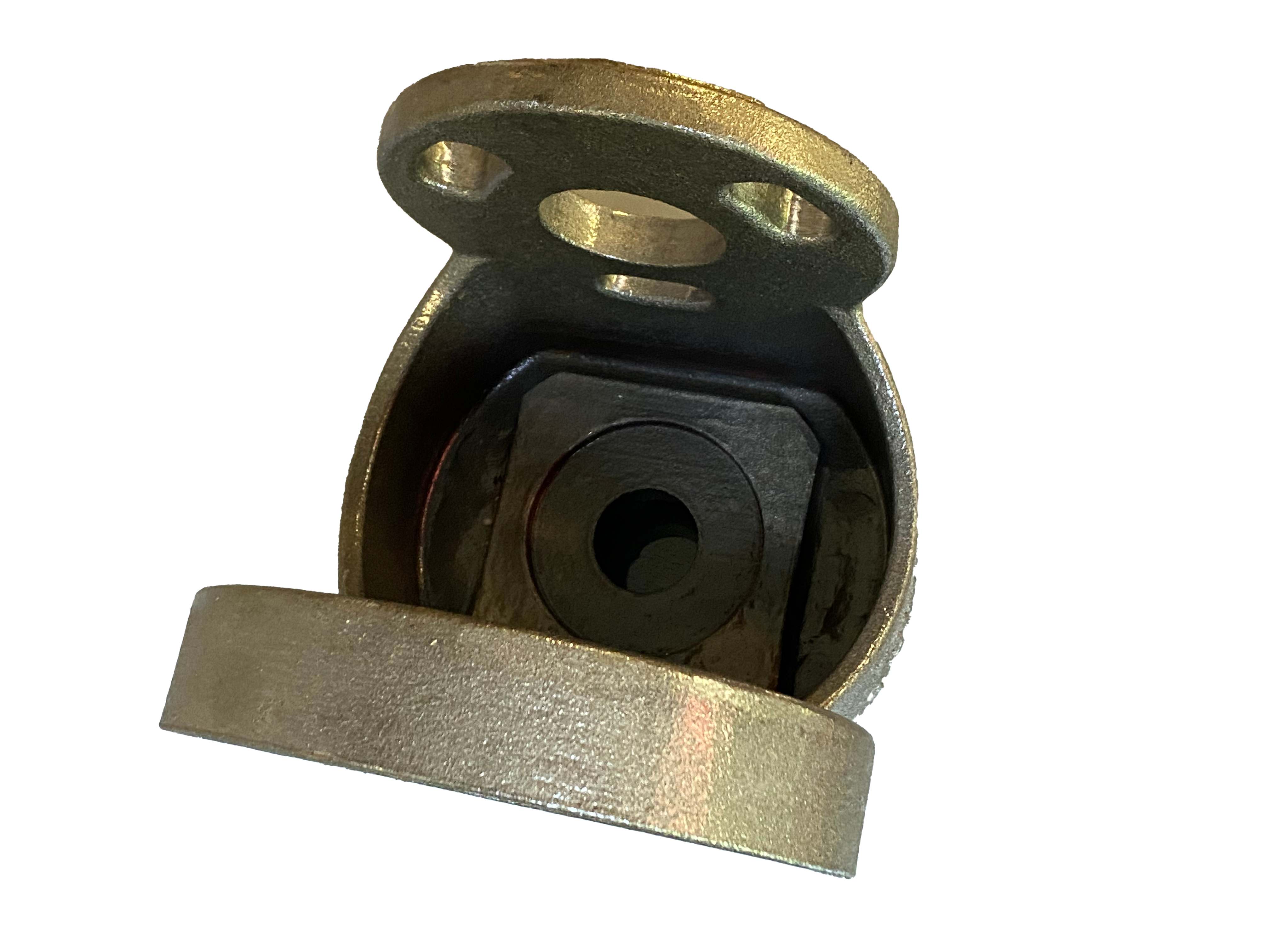

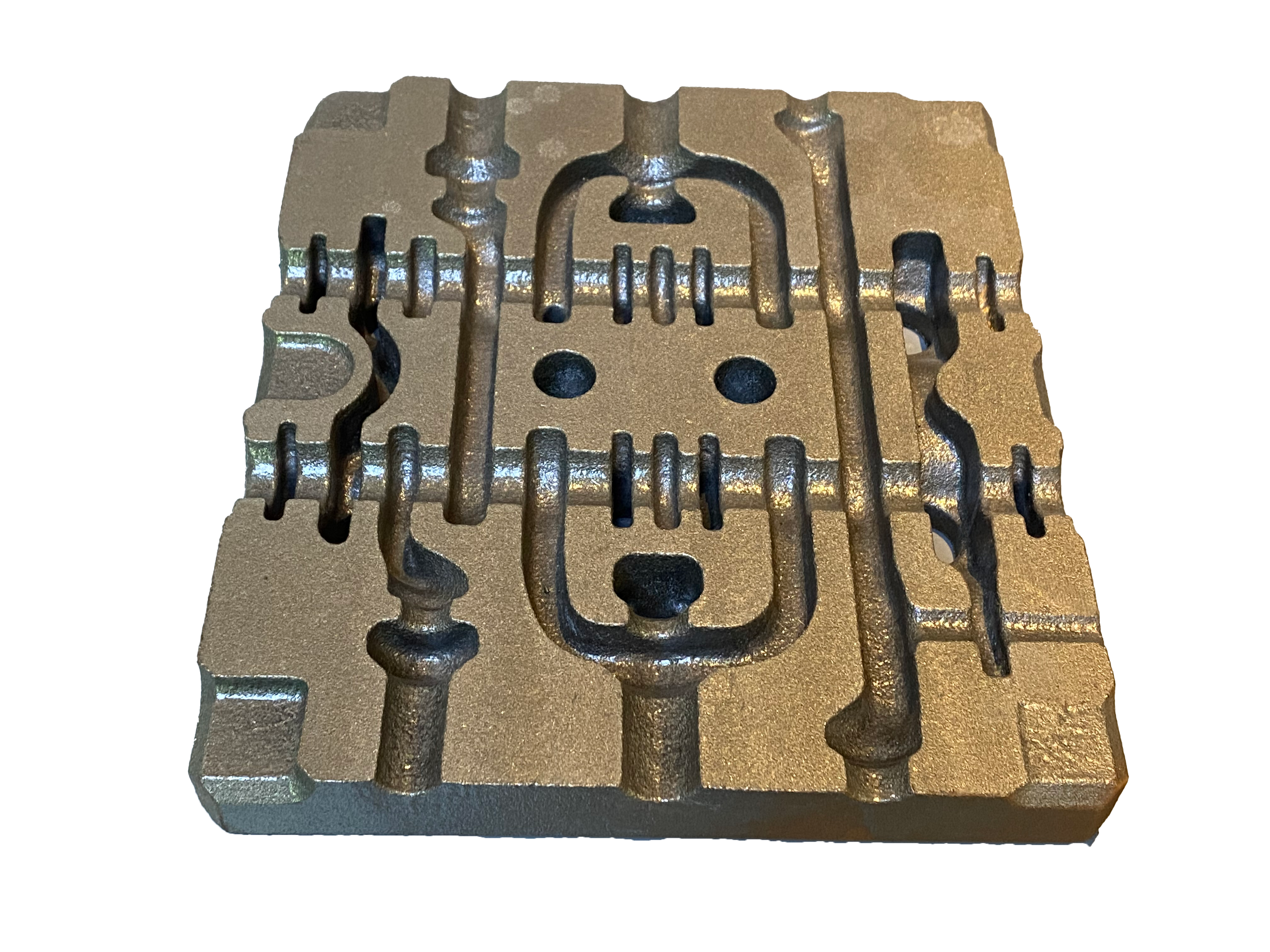

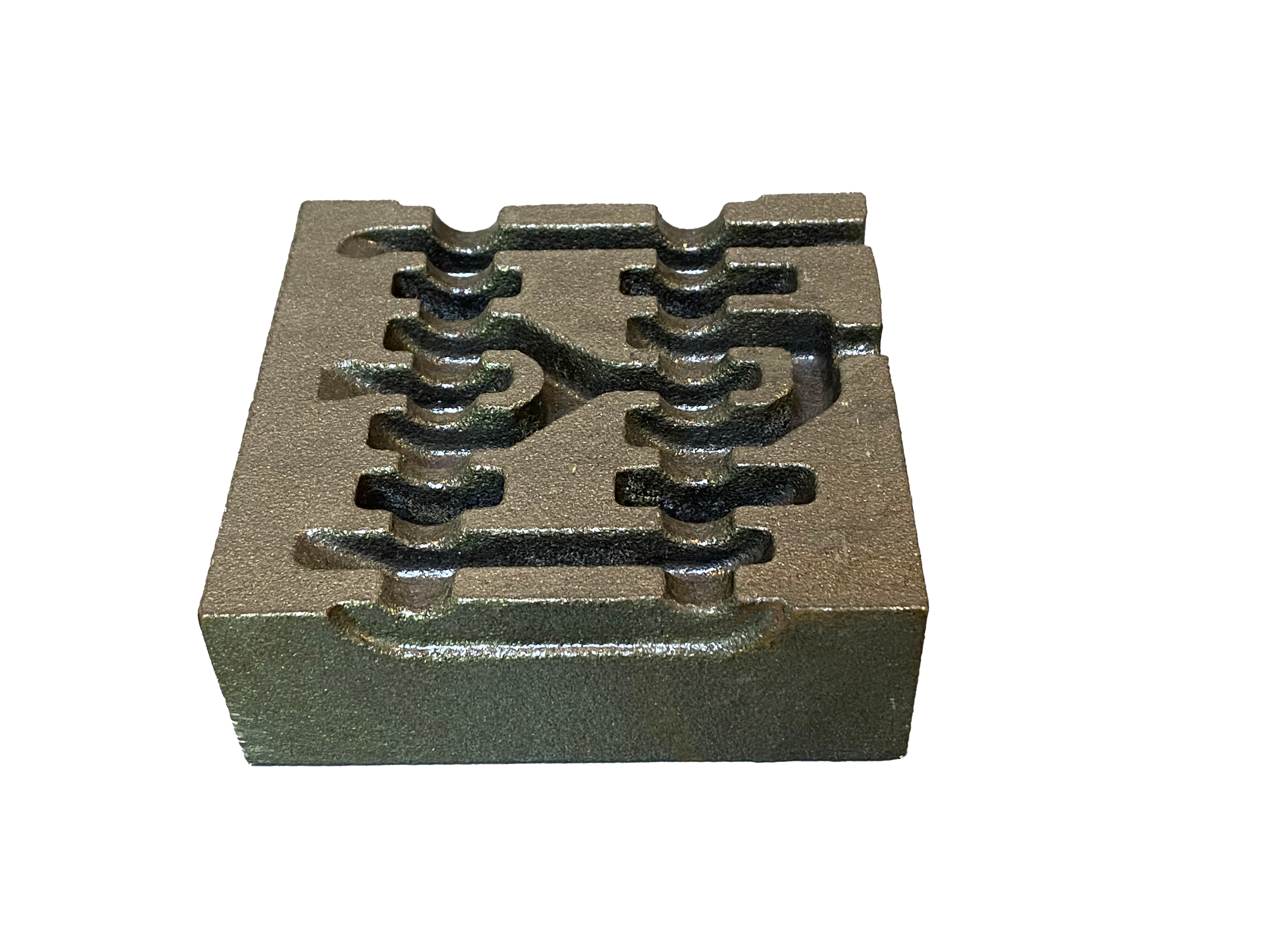

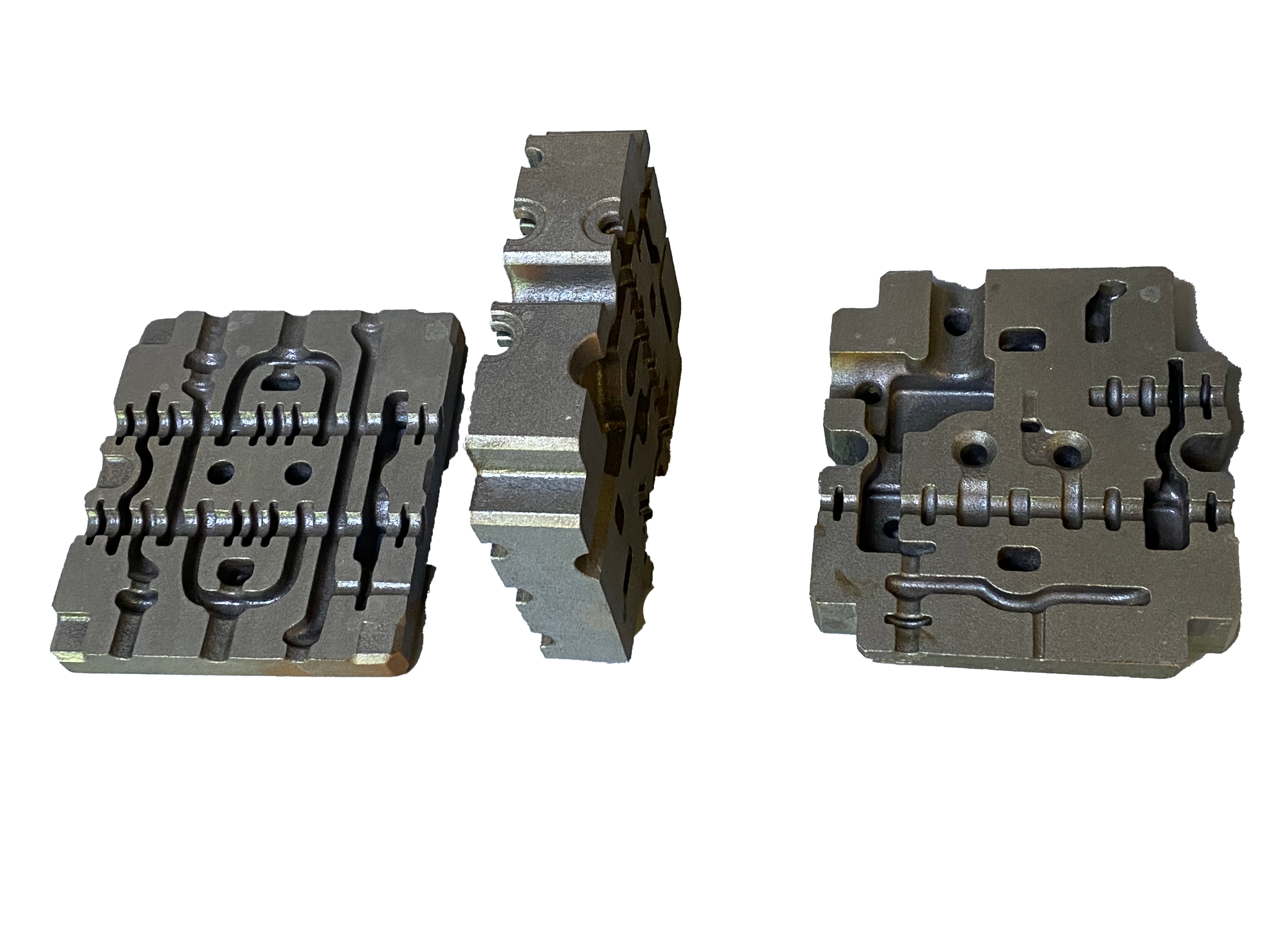

Iron casting

Kukandwa kunogadzirwa uchishandisa jecha nzira yekukanda inogadzirwa mujecha mold.Simbi, simbi, uye iyo yakawanda isiri-ferrous alloy castings inogona kugadzirwa uchishandisa jecha kukanda.Kukandira jecha kunogona kuchinjirwa kune imwe-chidimbu kugadzira, kugadzirwa kwebatch, uye kugadzirwa kwakawanda sezvo zvinhu zvekuenzanisira zvinoshandiswa mukuita izvi zvisingadhure uye zviri nyore kuwana, uye molds iri nyore kuvaka.Yave nenguva refu yakashanduka kuita nhanho yakakosha mukugadzira kugadzira.

Zvakanakira simbi yakaumbwa

- Inowanikwa muhuwandu hukuru, saka inogadzirwa muhuwandu hwehuwandu.Equipments for casting process zvakachipa.Saka mari yezvigadzirwa zvayo yakaderera.

- Inogona kupihwa chero chimiro chakaoma uye saizi pasina kushandisa inodhura machining mashandiro

- Iine katatu kana kashanu kuwedzera simba rekumanikidza zvichienzaniswa nesimbi

- Iyo ine yakanaka machinability yegrey cast iron.

- Iyo ine yakasarudzika anti-vibration (kana kunyorovesa) kuita, nekudaro inoshandiswa kugadzira muchina mafuremu

- Iine pfungwa dzakanaka

- Iyo ine yakanakisa kupikisa kupfeka

- Inogara iine ma mechanical properties pakati pe20 kusvika 350 degree Celsius

- Iine yakaderera notch sensitivity

- Iine low stress concentration

- Inotakura mutengo wakaderera

- Hune kusimba kwakanyanya

- Iine maitiro akanaka ekupikisa deformation

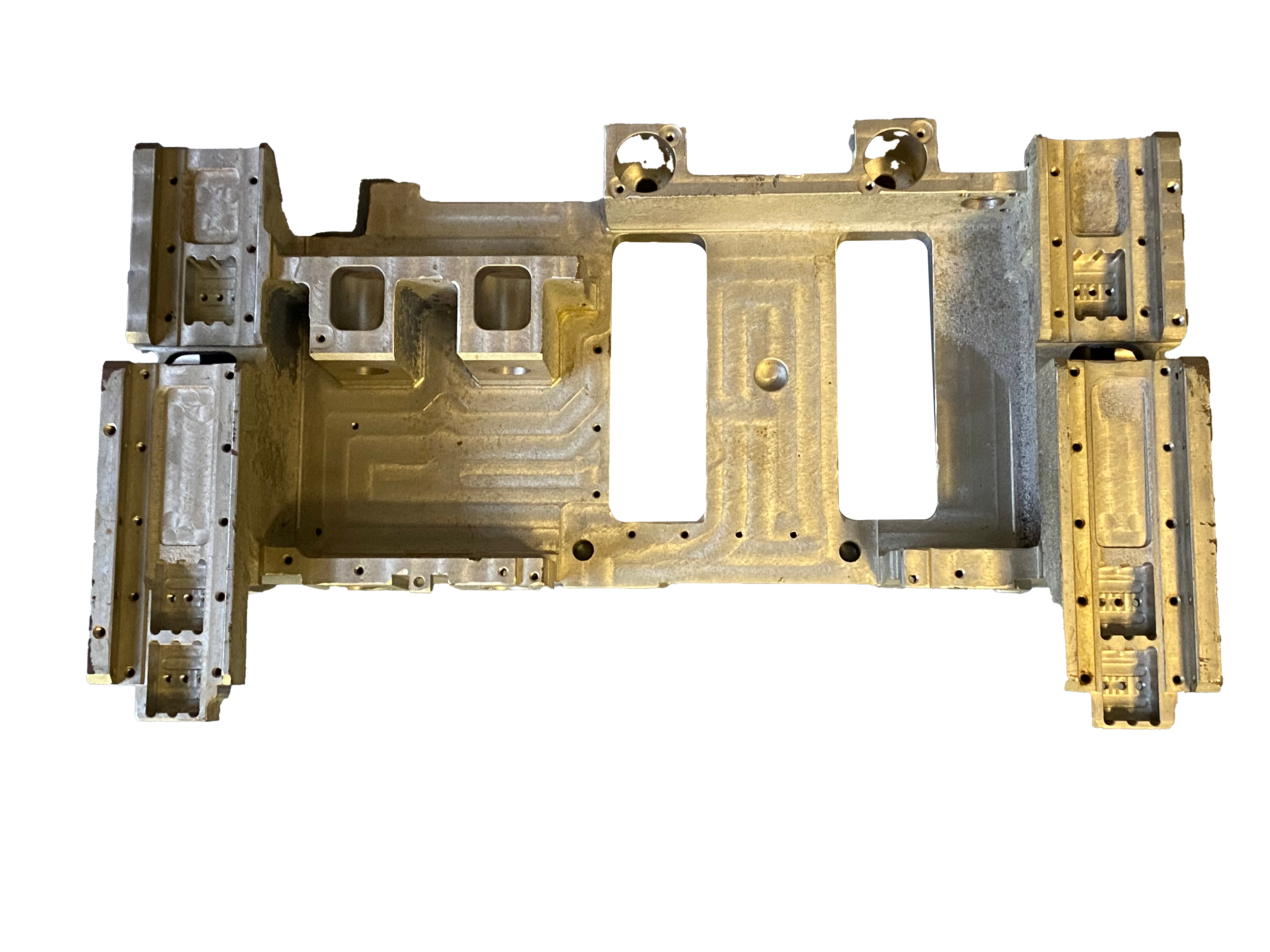

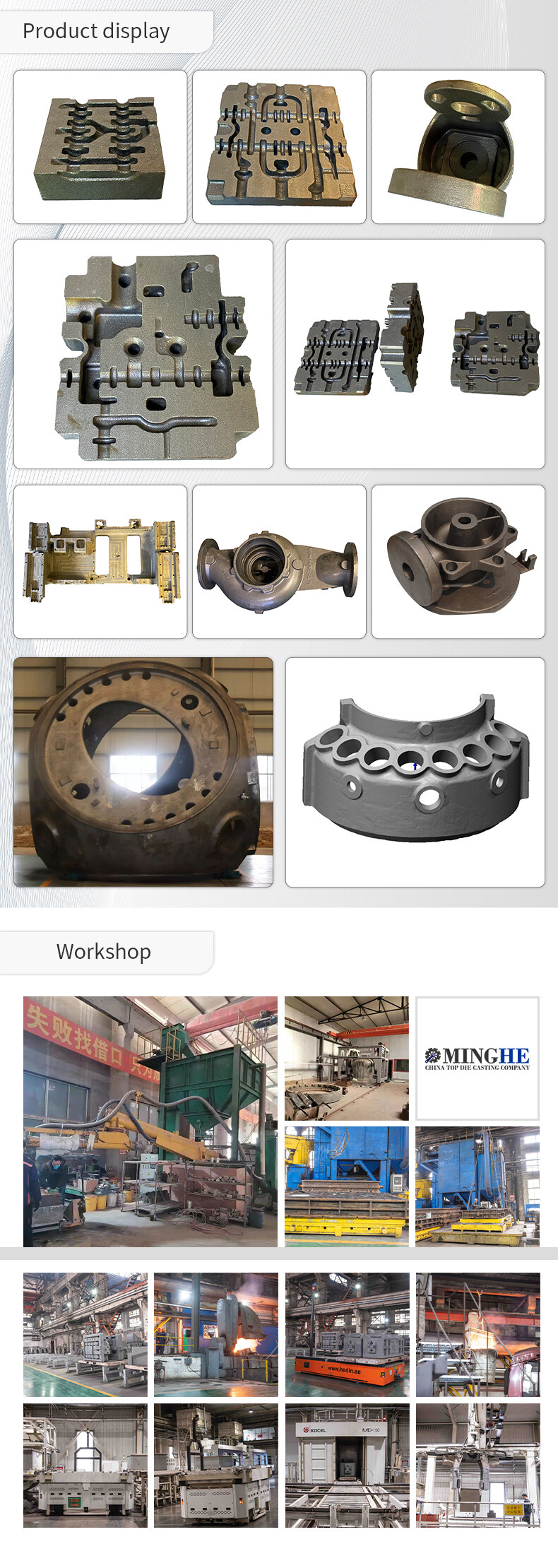

Iron Casting Process MuMINGHE

MuMinghe, kune nzira mbiri huru dzekukanda simbi: kukanda jecha kana kurasika furo nzira.

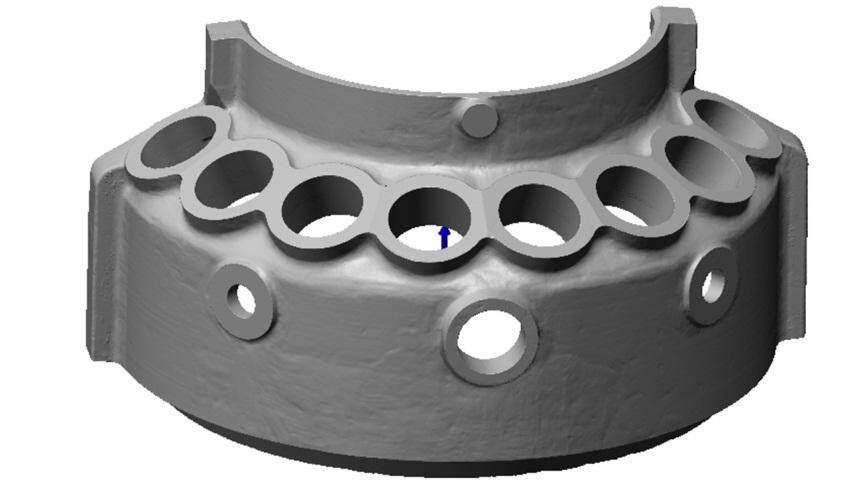

Kukanda jecha

Kukandira jecha inzira yekukanda iyo inogadzirwa mujecha mold.Kuburikidza nekukanda jecha, simbi, simbi uye akawanda asiri-ferrous alloy castings anogona kuwanikwa.Zvinhu zvekuenzanisira zvinoshandiswa mukukandira jecha zvakachipa uye zviri nyore kuwana, uye molds ari nyore kugadzira, saka kukanda jecha kunogona kuenderana nekugadzirwa kwechidimbu chimwe chete, kugadzirwa kwebatch uye kugadzirwa kwakawanda.Yakave nzira yekutanga mukukanda kugadzirwa kwenguva yakareba.

Zvinhu zvekutanga zvekugadzira zviumbwa zvejecha ijecha rekuwana uye jecha binder.Silicous jecha ndiro rinonyanya kushandiswa foundry jecha.Kana iyo yepamusoro-tembiricha kuita kwe silica jecha haigone kusangana nezvinodiwa zvekushandisa, jecha rakakosha senge zircon jecha, chromite jecha, uye corundum jecha rinoshandiswa.Izvo zvinodikanwa kuwedzera jecha bhainda mukukanda kuti ribatanidze yakasununguka jecha zvimedu kuti riite jecha kuti riite rakapedzwa jecha mold uye musimboti rive nerimwe simba uye risave kunze kwechimiro kana kukuvadzwa mukubata, kuumba uye kudurura. mvura yesimbi.Iyo inonyanya kushandiswa kuumba jecha binder ivhu, uye akasiyana-siyana anoomesa mafuta kana semi-anoomeswa oiri, mvura-inonyungudika silicates kana phosphates uye akasiyana ekugadzira resins anogona zvakare kushandiswa sekuumba jecha bhandi.Zviumbwa zvejecha rekunze zvinoshandiswa mukukanda jecha zvinogona kuiswa mumhando nhatu: jecha revhu rakasvibira, ivhu rakaoma jecha nejecha rakaomeswa nekemikari zvichienderana nebhainda rinoshandiswa mujecha uye magadzirirwo aro simba.

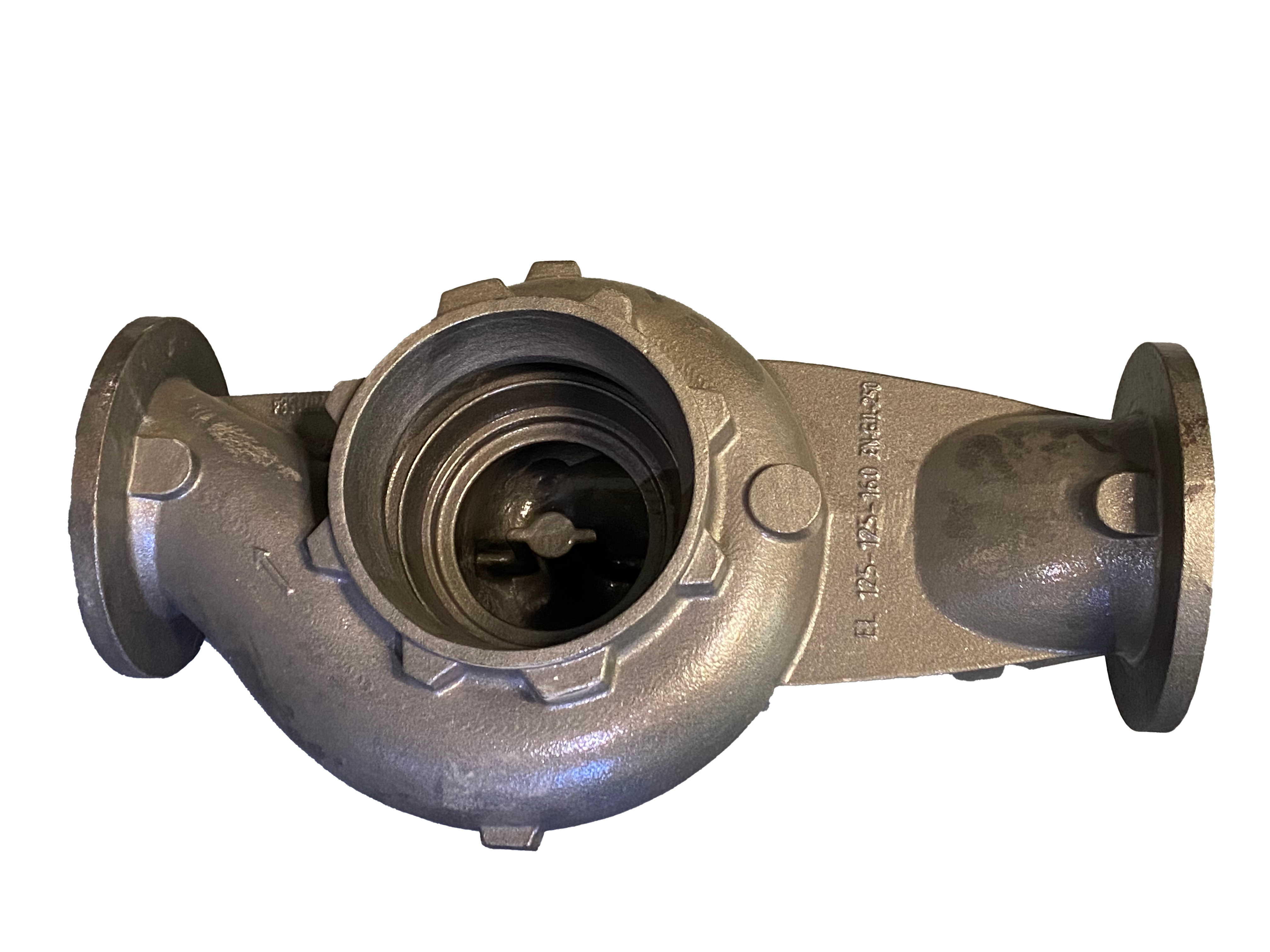

Kurasika furo

Lost Foam Casting ndeyekusanganisa wakisi yeparafini kana furo modhi dzakafanana muhukuru uye maumbirwo kune zvinokandwa kuita masumbu.Mushure mekukwesha uye kuomesa refractory coatings, ivo vanovigwa yakaoma quartz jecha nokuda vibration modelling.Iyo inzira nyowani yekukanda iyo inoita kuti modhi iite gasify, simbi yemvura inogara pachinzvimbo chemuenzaniso, uye inoomesa uye kutonhora.

Sezvo jecha rakaoma risina binder rinowanzoputsika panguva yekudira, A. Wittemoser muGermany akatora iyo inonzi "magnetic casting" muna 1967. Muna 1971, Nagano weJapan akagadzira nzira yeV (vacuum casting method).Kufemerwa neizvi, kukanda furo kwanhasi kwakarasika kunoshandisawo vacuum kugadzirisa jecha munzvimbo dzakawanda.Naizvozvo, tekinoroji yekukanda furo yakarasika yakakurumidza kukura pasi rese mumakore makumi maviri apfuura.

FAQ

Nzira yekuraira?

Chekutanga, Mutengi anogona kutitumira sampuli yako kana kudhirowa, senge 2D uye 3D kudhirowa (IGS kana STP fomati).Chechipiri, mainjiniya edu anotarisisa kudhirowa uye ozokupa mutengo uri nani.Chechitatu, Kana iwe uchibvuma, saka kurongeka kwakasimbiswa.

Factory yako iripi?

Fekitori yedu iri paDongguan rinova guta rakanaka riri padyo neGuangzhou neShenzhen.Unogona kubhururuka uchienda kuShenzhen Bao'an International Airport (ZGSZ) kana Guangzhou Baiyun International Airport (ZGGG), tichakutora panhandare yendege.

Iwe uri fekitori kana kambani yekutengesa?

Isu tiri fekitari.Isu tinokupa iwe-yekumira sevhisi, kubva pakugadzira mold kusvika kupedzisa chikamu.

Nzira yekutumira sei?

Muenzaniso wekukanda kufa uye CNC machining kana diki odha inowanzotumirwa neTNT, FEDEX, UPS nezvimwe, uye iyo hombe yekuraira inotumirwa nemhepo kana gungwa mushure mekusimbiswa kwevatengi.

Ndeipi mitemo yako yekubhadhara?

Kufa uchikanda mold kubhadhara: kubhadharwa kwepamusoro 40% mushure mekusaina chibvumirano;

Iyo 60% chiyero ichabhadharwa mushure mekubvumidzwa kwe mold nemutengi.

Nguva yekubhadhara yemirairo yekukanda kufa: T / T, 30% sedhipoziti inobhadharwa isati yagadzirwa neT / T, 70% inobhadharwa isati yasvika.